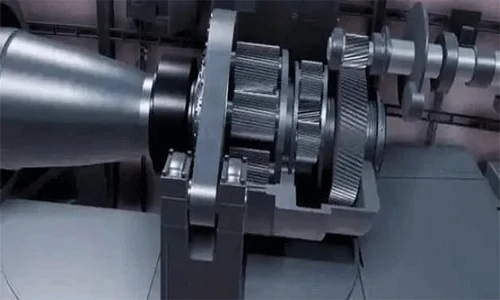

In Jilin Province’s CGNPC Yuantong Sankeliu wind farm, 30 smart wind turbines have been in operation for three years, using China’s independent research and development and production of sliding bearing gearboxes, and realized “zero failure”. This is the first time that sliding bearing gearboxes have been used in the domestic wind power field in large quantities, verifying the feasibility and reliability of the technology in wind power application scenarios.

According to the relevant person in charge of the wind farm, compared with the traditional rolling bearing gearbox, the sliding bearing gearbox can reduce the power loss of about 20%-25%. This means that under the same input conditions, the power generation of a wind turbine can be increased by about 0.5%. A 3.3 MW onshore wind turbine, for example, can generate an additional 1,075,140 kWh of electricity over its entire lifecycle, which is equivalent to the annual electricity consumption of 360 households.

The gearboxes are produced by an energy transmission chain factory in Jiangyin, Jiangsu Province. Vision Energy’s senior vice president noted that the successful application of the plain bearings was due to in-depth research on the technology, breakthroughs in melt-spray coating technology routes, and strict standards and precision testing during the manufacturing process. In addition, Vision also ensures the high reliability and performance of its products through in-depth mining of massive data and deep understanding of the operating conditions of wind turbines.

Key information on sliding bearings:

Sliding bearings: Sliding bearings rely on sliding between the friction surfaces to run, due to the lack of rolling body this structure is therefore relatively rolling bearings radial size is smaller, the movement is more stable, the bearing capacity is stronger. The disadvantage is that the friction coefficient during operation is large and energy consumption is high. Sliding bearing according to the friction surface of the lubrication form can be divided into fluid lubrication bearing and self-lubricating bearing:

(1) Fluid lubricated bearings: fluid lubricated bearings can be divided into dynamic pressure bearings and static pressure bearings according to different lubrication principles. Dynamic bearings are lubricated by the relative movement of the journal and the inner wall of the bearing, resulting in the formation of a film of fluid with a certain load-bearing capacity, which is generally suitable for high-speed operation. Hydrostatic bearings, on the other hand, use a pressure pump to force a pressurized lubricant into the small gap between the bearing and the shaft. It is characterized by the ability to establish a load-bearing oil film even in a stationary or low-speed scenario, and is suitable for low-speed running scenarios.

(2) self-lubricating bearings: self-lubricating bearings are made of self-lubricating materials or lubricants added to the materials in advance, in the work of the sliding bearings can be not added or a long period of time do not need to add lubricant, according to the nature of the lubricant can be divided into oil-containing bearings and solid lubricated bearings. Oiled bearings are classified into oil-containing bearings and solid-lubricated bearings according to the nature of the lubricant. Solid lubricated bearings are lubricated with solid lubricant materials such as PTFE and graphite instead of traditional lubricants.

With the increasing capacity of wind turbines, the application of traditional rolling bearings is approaching its limit. Sliding bearings are the ideal choice to support the continued large-scale development of wind turbines due to their small size, light weight and low power loss. Especially for long-life requirements of wind turbine equipment, plain bearings are better able to meet the requirements of the full life cycle of 25-30 years.

Domestic wind power manufacturing enterprises began to explore the research and development of sliding bearing gearboxes as early as five years ago. At present, only Vision Energy has realized the self-research and production of plain bearings and has batch production capacity. As of 2023, Vision Energy’s offshore wind turbines equipped with plain bearings have been grid-connected in Shandong waters, with a total of more than 100 turbines maintaining the record of “zero failure”.

The technical difficulties of plain bearings lie in their complex manufacturing process and strict cleanliness control. For example, a thin, lightweight, anti-friction protective layer is added to the surface of the bearings through melt-spray coating technology, and then a series of precision processes are carried out to ensure product quality. Vision Energy not only pays attention to product design and manufacturing, but also simulates various actual working conditions during the testing and verification process to ensure that the performance of the components meets the requirements.

The successful application of this sliding bearing gearbox not only marks a major technological advancement in China’s wind power industry, but also provides valuable experience for the application of sliding bearings in other industrial fields. Sliding bearings also have a wide range of application prospects in automobile gearboxes, marine engines and other fields, and their breakthrough will promote the development of the entire high-end basic parts industry. This achievement reflects the leapfrog development of China’s wind power industry from following to leading, and demonstrates the strength and commitment of Chinese enterprises in global technological innovation.